BLOG

Mastering Heat Transfer Vinyl: A Complete Guide to Using Your Cricut Machine

Mastering the art of using Heat Transfer Vinyl (HTV) can elevate your crafting game to a whole new level, allowing you to produce vibrant, personalized designs for garments and other fabric-based projects with your Cricut machine. HTV is a versatile material that can easily be shaped, cut, and transferred onto fabric using heat and pressure. This complete guide will take you through everything you need to know about HTV, from understanding its fundamental properties to getting started with your Cricut machine, and preparing compelling designs that will make your projects pop. Whether you’re an experienced crafter or a complete beginner, this guide aims to empower you with the knowledge needed to make the most out of your HTV experience.

Introduction to Heat Transfer Vinyl

What is Heat Transfer Vinyl?

Heat Transfer Vinyl (HTV) is a type of vinyl that is specially formulated to be applied to fabric using heat and pressure. Unlike adhesive vinyl, which is typically used for hard surfaces, HTV is designed to adhere to textiles, making it ideal for customized apparel, tote bags, and home decor items. HTV comes in a variety of types, including standard, glitter, glow-in-the-dark, and even holographic, allowing for endless creative possibilities.

When HTV is applied correctly, the result is a long-lasting design that withstands numerous washes without peeling or fading. The application process involves cutting your design from the HTV sheet, weeding out the areas you don’t need, and then using a heat press or iron to transfer the vinyl onto your chosen fabric. This method ensures that the design becomes an integral part of the material rather than simply sitting on top, creating a professional-quality finish.

Advantages of Using HTV

Using Heat Transfer Vinyl has several advantages that make it an appealing choice for crafters and small business owners alike. First and foremost, the ability to create custom designs empowers users to produce unique apparel that stands out, whether for fashion statements, promotional items for businesses, or special events.

One of the significant benefits of HTV is its durability. Properly applied HTV can withstand many wash cycles without losing its integrity or vibrancy, making it suitable for everyday wear. For businesses, this means customer satisfaction and repeat sales, as buyers appreciate high-quality items that maintain their appearance over time.

Furthermore, HTV is available in a multitude of colors and finishes, allowing for creativity in design. It’s also user-friendly. Even those without extensive experience can learn to work with HTV quickly, especially with the help of machines like Cricut that simplify the cutting and application process.

In terms of cost-effectiveness, HTV is relatively affordable compared to other customization methods like screen printing, especially for small runs or one-off projects. There’s no minimum order quantity, which makes it perfect for personalized gifts, wedding favors, or custom merchandise for small businesses.

Getting Started with Your Cricut Machine

Choosing the Right Cricut Model

Embarking on your HTV journey with a Cricut machine starts with selecting the right model. Among the various options available, each machine comes with unique features suited for different levels of crafting and customization needs. For beginners or casual crafters, the Cricut Explore Air 2 offers a balance of user-friendliness and versatility, allowing you to cut a wide range of materials, including HTV, with ease.

For those looking for more advanced capabilities, the Cricut Maker provides additional cutting options, including rotary blade cutting for fabric, which is ideal for more intricate designs or projects that require sewing. The Maker’s adaptive tool system allows for future upgrades, making it a long-term investment for serious crafters.

It’s also worth considering the size of the machine and the workspace available. The design size will affect not only your project options but also how much HTV you will need to buy at once and where you can effectively work on your project.

Necessary Tools and Supplies

Once you’ve chosen your Cricut model, it’s crucial to gather the necessary tools and supplies to start your HTV projects. Beyond the Cricut machine itself, essential items include:

- Heat Transfer Vinyl: Available in various types (e.g., standard, glitter, flocked) and colors.

- Cutting Mat: A standard grip cutting mat is often recommended, which holds your material in place during cutting.

- Weeding Tools: These sharp tools, such as tweezers or hook tools, are necessary for removing excess vinyl after cutting.

- Heat Press or Iron: While an iron can work for smaller projects, a heat press machine provides even heat distribution and pressure, ensuring a better adherence of HTV to fabric.

- Protective Sheet (Teflon Sheet or Parchment Paper): Using a protective sheet during heating will prevent scorching and safeguard your press or iron.

- Scissors: Handy for trimming your HTV if needed.

Taking time to invest in quality supplies will pay off, resulting in cleaner cuts and effective transfers.

Preparing Your Design

Software Options for Designing

Designing your HTV project is an integral step in the process, and Cricut offers several software options to help you. The most popular is Design Space, which is compatible with all Cricut machines. This cloud-based software is user-friendly and allows you to create custom designs from scratch or use pre-made templates. It features a library of images, fonts, and tools that can be directly integrated with your Cricut machine for an easy workflow.

For those who prefer more advanced design capabilities, software like Adobe Illustrator or CorelDRAW can be utilized. These programs offer extensive design tools and precise control over elements but require an additional step to save your creations in a format compatible with Cricut (e.g., SVG files).

Using templates can make the design process quicker and easier, especially for those who may be less confident in their design abilities. Websites like Etsy and Creative Market offer a myriad of SVG files that can be purchased and downloaded, ready to cut.

Tips for Creating Effective HTV Designs

When it comes to crafting your own HTV designs, several key considerations can enhance the effectiveness and overall aesthetic of your projects. First, always remember that HTV needs to be mirrored before cutting. This is essential because the design will be flipped onto the fabric in reverse, ensuring that it appears correctly when applied.

Next, consider the complexity of your design. While intricate designs are visually appealing, they may also be challenging to weed, particularly for beginner crafters. Opt for simpler designs or ensure that you invest time in weeding tools that facilitate the process.

Color contrast is also crucial; ensure that your chosen HTV color stands out against the fabric. Light colors on dark fabric and vice versa often yield the best results. Additionally, using layering techniques can enhance your designs—utilizing multiple colors and types of HTV can add dimensions and a unique touch to your project.

Understanding the fabric type is paramount as well. Certain fabrics have different heat settings, and knowing how much heat your chosen material can withstand will ensure you don’t damage it. Fabrics like cotton typically handle HTV well, while more delicate materials such as nylon or polyester may require lower temperatures and less time when applying heat.

Lastly, testing on scrap materials before committing to your final project can save time and frustration. By trying earlier designs or techniques on scraps, you can make adjustments as necessary without the risk of ruining your intended project.

By fully understanding these elements of designing with HTV, you can confidently create vibrant, dynamic projects that showcase your creativity.

Cutting Heat Transfer Vinyl

How to Set Up the Cricut for Cutting HTV

Setting up your Cricut machine for cutting heat transfer vinyl (HTV) is a crucial step that impacts the quality of your final project. First, ensure that you are working in an environment that is clean and free from interruptions, as dust and debris can affect the cut quality.

- Select the Right Material: Before you start, choose your HTV. There are various types of HTV, such as glossy, matte, and glitter. Each has different cutting requirements, so always refer to the product instructions for the best practices.

- Load Your Design: Using Cricut Design Space, create or import your design. It’s important to remember to mirror your design before cutting HTV. This is essential because HTV is applied with heat, and the image must be reversed for it to appear correctly on the fabric once applied.

- Select the Correct Settings: When your HTV is loaded onto the cutting mat, select the appropriate material setting in Design Space. For most standard HTV, choose “Iron-On.” If you’re using specialty materials, like flocked vinyl or holographic HTV, select accordingly. Advanced users also might opt for the Custom settings for more precise adjustments.

- Blade Adjustment: Ensure that your Cricut blade is sharp; a dull blade can lead to incomplete cuts. Standard HTV typically requires a fine point blade, set at a depth of 2 to 3 for most machines. Always perform a test cut if you’re uncertain.

- Load Mat and Start Cutting: Place your HTV shiny side down on the mat, load the mat into the Cricut machine, and begin the cutting process. After the machine has finished, carefully unload the mat by pressing the unload button.

Troubleshooting Common Cutting Problems

Even seasoned crafters experience issues while cutting HTV. Common problems include incomplete cuts, unclean edges, or tearing in the material. Here’s a guide to troubleshooting:

- Incomplete Cuts: If the design is not cut through entirely, check your blade condition. A dull blade can leave portions uncut. Adjust the pressure settings for cutting in the design software, and reconsider your material thickness; you may need to change to a thicker material setting.

- Tearing of Vinyl: If the HTV tears during cutting, it is possible that the blade depth is too deep, or your material is not properly adhered to the mat. Test a new mat or ensure the mat is sticky enough to hold the material firmly in place.

- Unclean Edges: If the edges of your design appear jagged or rough, ensure that your cutting settings are calibrated correctly. Additionally, check that the HTV is resting smoothly on the mat, without air bubbles that could interfere with a clean cut.

- Vinyl Moving During Cut: If you notice shifting during the cutting process, it could be due to a low-quality mat. Ensure that your mat has adequate adhesive; if it is too old, consider replacing it.

Through these troubleshooting steps, you can enhance the accuracy and efficiency of your cuts, ensuring a professional finish to your HTV projects.

Application Techniques

Best Practices for Applying HTV

Proper application of heat transfer vinyl is as critical as cutting. Here are best practices to ensure a successful transfer:

- Preheat Your Heat Press: Always preheat your heat press or iron before applying HTV. This will help to eliminate moisture in the fabric and create a better bond between the vinyl and the material. A temperature of around 320°F is typically recommended for most HTV types.

- Use a Teflon Sheet or Parchment Paper: Place a Teflon sheet or parchment paper on top of the HTV before applying heat. This helps distribute the heat evenly and protects the vinyl from direct contact with the heat source, reducing the chance of scorching.

- Press Firmly and Evenly: Apply firm and even pressure across the design when using a heat press. For home irons, use a consistent downward pressure for about 15-20 seconds for most HTVs, ensuring that you cover all parts of the design.

- Cool Peel vs. Warm Peel: Follow the manufacturer’s instructions on whether to peel the carrier sheet when hot or cold. Most standard HTVs require a warm peel, while specialty materials like glitter may suggest a cold peel.

- Final Press: After removing the carrier sheet, perform a final press over the design for 10-15 seconds. This step secures the vinyl onto the fabric and ensures its longevity.

Common Mistakes to Avoid

Even the most seasoned crafters can overlook fundamental application techniques that lead to unsatisfactory results. Here are some mistakes to avoid:

- Skipping the Preheat: Failing to preheat the fabric can lead to a poor bond and cause the vinyl to peel off over time.

- Insufficient Pressure: Not applying enough pressure can result in lifting edges, especially after washing. Ensure that you press firmly while applying heat.

- Ignoring Fabric Type: Different materials react differently to heat transfer. Applying HTV to fabrics that are not suitable, such as nylon or some stretchy fabrics, might result in issues like bubbling or peeling. Always consult fabric-specific guidelines.

- Improper Storage of HTV: Exposure to light, heat, and humidity can degrade HTV. Store vinyl rolls upright in a cool and dry place, away from direct sunlight, to maintain their quality.

By adhering to these best practices and avoiding common mistakes, you can maximize the durability and appearance of your HTV projects.

Caring for Your HTV Projects

Washing and Maintenance Tips

Caring for HTV designs properly is essential for ensuring their longevity. Here are some washing and maintenance tips to consider:

- Wait Before Washing: After application, wait at least 24 hours before washing the garment. This gives the adhesive time to fully bond with the fabric.

- Use Cold Water: When it comes to washing HTV, cold water is your best friend. Hot water can cause the vinyl to lift or distort, leading to a potential disaster.

- Turn Inside Out: Always turn the garment inside out before washing. This protects the HTV design from friction against the washing machine drum and ensures less fading.

- Gentle Cycle: Use a gentle cycle on your washing machine; this reduces wear and tear on both the fabric and the vinyl.

- Avoid Fabric Softeners and Bleach: Fabric softeners can create a barrier that could prevent the adhesive from properly bonding, and bleach can discolor the vinyl. Opt for a mild detergent without harsh chemicals instead.

Longevity of HTV Designs

The longevity of HTV designs can vary significantly based on several factors, including the quality of the HTV used, application methods, and care post-application. High-quality HTV brands typically guarantee durability for up to 50 washes, but this can extend further with proper care.

To analyze the longevity factor:

- Quality of HTV: Investing in reputable brands like Siser or Cricut can result in better durability over time compared to lower-quality options. Researching and reading reviews about specific HTV types can guide your purchase decisions.

- Proper Application: Adhering to correct temperature and pressure settings during application is crucial. Missed details during this stage may compromise longevity.

- Fabric Care: The type of fabric also plays a vital role. Natural fibers like cotton tend to hold HTV better than blended or synthetic materials, which might not bond well under varying washing conditions.

Through attentive care, you can ensure that your handmade designs remain vibrant and intact, preserving the time and creativity you invested into each project.

Creative Project Ideas

While many projects can benefit from heat transfer vinyl, especially when using a Cricut machine, getting creative with HTV can transform ordinary items into unique pieces. Here are some ideas to inspire your next crafting session:

- Customized Apparel: From t-shirts to hats, customized apparel using HTV is perhaps the most common application. By creating unique designs, logos, or even personal quotes, you can express individual style or create personalized gifts.

- Home Decor Fabrics: Utilize HTV on fabric items such as throw pillows, curtains, or table runners. Create personalized designs like monograms or thematic patterns for specific rooms in your home.

- Bags and Backpacks: Customize tote bags, backpacks, or even lunch bags with fun graphics or personal identifiers. This is particularly helpful for keeping children’s belongings easily recognizable at school or daycare.

- Seasonal Decorations: Using HTV, you can create festive home decorations for holidays. Ideas include customized ornaments, decorative pillows with seasonal phrases, or even themed tea towels for holiday gatherings.

- Party Supplies: Personalize party decor with HTV, from birthdays to weddings. Create banners, tablecloths, or event-specific garments for hosts and guests.

By tapping into the diverse applications of HTV, you can not only hone your skills but also explore your creativity, leading to more rewarding crafting experiences and memorable gifts.

Custom T-Shirts and Apparel

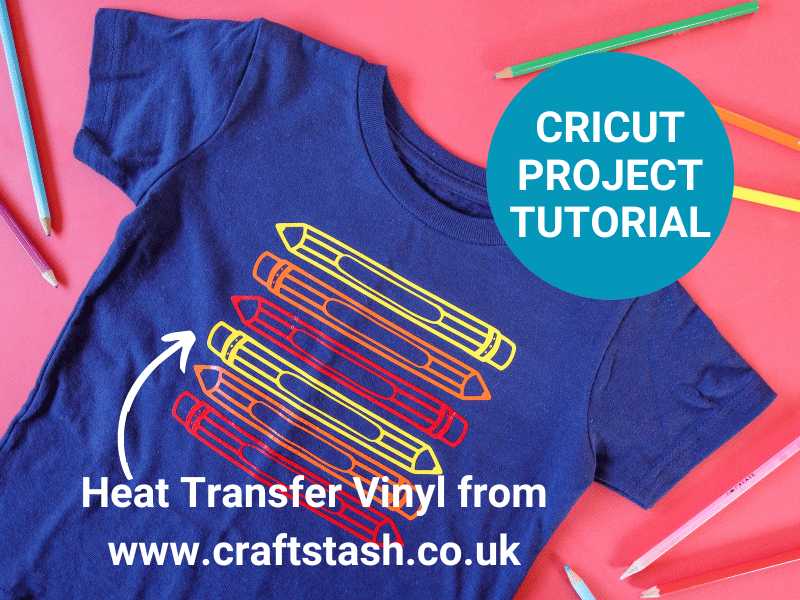

Customizing t-shirts and apparel using heat transfer vinyl (HTV) is one of the most popular applications of Cricut machines. This method allows users to express their creativity, commemorate special events, and even promote businesses through personalized garments. The process typically begins with selecting the right type of HTV, which can vary in finish—glossy, matte, metallic, holographic, and more. Each type lends a unique aesthetic and can influence the overall design outcome.

When embarking on a t-shirt project, it’s crucial to consider the fabric type as well. HTV adheres best to cotton, polyester, and blends of these materials. For instance, a 100% cotton t-shirt will yield different results than one that is primarily polyester due to their heat sensitivity and melting points. Additionally, some vinyl types work better with specific fabrics. For example, Siser EasyWeed HTV is known for its versatility and ease of use across various fabric textures, making it a favorite among DIY enthusiasts.

Lastly, designing for t-shirts or apparel usually involves creating graphics in a vector format that can be scaled without losing quality. Using software like Cricut Design Space, hobbyists can manipulate images, add text, and even import files to craft intricate designs. After the design is finalized, it’s cut with the Cricut machine. Users should remember to mirror their designs before cutting since HTV is applied face down. Once cut, the heat transfer vinyl must be weeded—removing excess material—before it can be transferred onto the fabric using a heat press or an iron.

Real-world examples include creating custom t-shirts for family reunions, charitable events, or even small business ventures. Statistics show that the custom apparel market is projected to reach $10 billion by 2025, indicating a growing interest in personalized clothing and the opportunities it presents. With the right tools, techniques, and a bit of creativity, custom t-shirts become not only a canvas for artistic expression but also a source of income for many DIYers.

Home Decor Projects

In addition to apparel, heat transfer vinyl is a versatile medium for home decor projects. HTV can be used to personalize and transform a wide range of home items, from pillow covers and wall decals to kitchen towels and table runners. The ability to customize decor pieces according to one’s individual style adds a personal touch to any living space.

For instance, a common home decor project involves creating decorative pillow covers. Begin with a plain pillow cover in a fabric compatible with HTV, such as cotton or polyester. Design an eye-catching graphic or a meaningful quote using Cricut Design Space, ensuring it aligns with the aesthetic of the room. Once the design is ready, cut the HTV and weed out the excess to prepare it for transfer. The application process involves setting a heat press or iron to the appropriate temperature, approximately 305°F for most HTV, and carefully transferring the design onto the pillow cover. This process not only enhances the decor but also provides a unique way to incorporate personal phrases or images that resonate with the homeowner.

The versatility of HTV also extends to creating unique wall art. Users can design personalized wall decals that can be applied to various surfaces, including walls, doors, or furniture. Seasonal decor is another popular application—think of creating temporary seasonal signs that can be displayed during holidays or special events, offering fresh decor without the need for permanent changes.

Moreover, statistics reveal that the home decor industry in the United States alone was valued at over $240 billion in recent years, with DIY decor and personalized items continuing to gain traction. Crafters who master HTV can tap into this lucrative market, either to beautify their own homes or to create products for resale. As home decor trends lean increasingly toward personalization and unique aesthetics, the demand for HTV projects is likely to grow, making it an exciting area for crafters to explore.

Conclusion

Recap of Key Points

To effectively master heat transfer vinyl with a Cricut machine, one must understand the diverse applications it offers, from custom t-shirts and apparel to innovative home decor. Each project entails selecting the right materials, careful design execution, and proper application techniques to achieve desired results. Custom apparel allows for self-expression and entrepreneurship, while home decor projects offer opportunities for personalization and creativity within living spaces.

Encouragement to Start Crafting

Whether you are a seasoned crafter or a beginner, now is an excellent time to dive into the world of heat transfer vinyl crafting. With a wealth of resources, including tutorials and community support through social media and crafting forums, anyone can learn effective techniques to enhance their projects. The tools provided by Cricut machines empower crafters to push the boundaries of their creativity and explore innovative design possibilities.

Embrace the challenges and joys of crafting with HTV. Dive into the vibrant communities of DIY enthusiasts, share your creations, and take pride in your ability to transform simple materials into personalized works of art. The journey of mastering heat transfer vinyl is not just about creating beautiful items—it’s about expressing yourself, celebrating special moments, and sharing your unique vision with the world. So gather your materials, spark your imagination, and start crafting today!